Specializing in Superior Quality Coils - Made in the USA

E-mail:

Stay Connected

(40º F and above) This coil looks and operates very much like a hot water coil. It's almost always a 1 or 2-row coil, and the steam enters and leaves just like hot water. The major difference in the construction is that the tubes and return bends are heavier wall copper and the brazing process is upgraded. Always remember that even low-pressure steam is more erosive that hot water and a steam coil needs to be built accordingly. Also, Standard Steam coils must be used with entering air above 40º. If you pass colder air across this type of coil, you will freeze it immediately.

Steam is not hot water and even low-pressure steam needs to be handled completely differently that hot water, When you build a standard steam coils, you have several different options regarding the construction.

Steam requires a whole set of controls and valves that are not present with hot water. This is important, because both performance and life expectancy of standard steam coils is directly tied into how well these controls are designed. This is not true for any other type of coil. If you select the wrong type of trap or place it incorrectly in the system, then the coil will probably fail prematurely. Often you will require vacuum breakers as well.

Standard steam coils come in two different diameters, either 5/8" or 1". Standard team coils are available only in 5/8". There are many 100% outside air preheat applications that require a large lbs./hr. of steam input. As a result, these applications develop a lot of condensate, and it's impossible to evacuate this amount of condensate from a small 5/8" tube. The coils just backup the steam, because the condensate has nowhere to go. When you have this kind of job, a 1 " steam distributing coil is what you want to use. Basically steam coils fail far more often than other types of coils, because everything about them is more complicated. In the plan & spec market, everybody is trying to take "shortcuts" to get the job and as a result, there are many misapplications.

If you ever have any questions or need advice on CONTACT US TODAY!

Surefin offers replacement for any size steam coil, even custom ones.

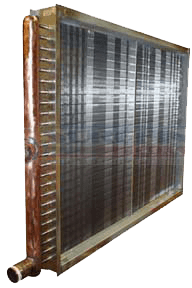

Steam Coils are used for heating applications and are built to operate at pressures of up to 125 PSIG with a maximum temperature of 353°F. They are pressure tested with 600 PSIG of dry nitrogen. The most frequent use of steam coils is for retrofitting or modifying existing steam heat systems.

Standard steam coils are used in a variety of high and low pressure applications and are designed to handle large amounts of steam and to provide quick condensate removal. Uniform steam distribution to each of the coil core tubes is accomplished by proper header assembly design.

To get a Steam Coil price or other custom coil pricing CONTACT US today!